LUMBER WITH A UNIQUE STORY

Clover Construction offers the unique service of on-site log milling with their Woodmizer LT35 portable hydraulic band saw mill. This allows them to mill logs up to 32” in diameter into usable lumber. The mill is mobile, allowing simple setup on site. Clover Construction can also mill at their business location, if preferred.

As a residential General Contractor, many customers must have, or have had, timber cleared from their property during the initial stages of their project. Many of Clover Construction’s Clients choose to mill their logs into usable lumber.

There are some fantastic benefits to milling your own logs: Rough-sawn lumber milled from your own trees is a conversation piece! Our clients have the pleasure of sharing the story of the wood’s origin with their family and friends, which adds to the overall value & enjoyment of their building experience. The “rough-sawn” lumber look is timeless and classic. And lastly, lumber is valuable! Don’t just turn it into firewood, incorporate it in your next project!

This image features a Black Walnut Slab that was “Book- Matched” for a furniture maker to turn into a kitchen table. Book matching is the practice of matching two wood surfaces, so that adjoining surfaces mirror each other, giving the impression of an open book.

CONSIDERATIONS BEFORE MILLING

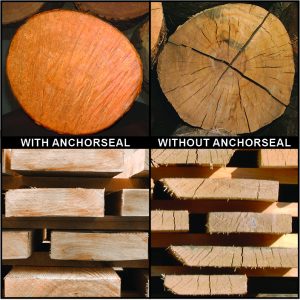

One popular technique is called “Canting.” A cant is the term used to describe a log that has been edged (squared) on all four sides. Canting logs provides several benefits: the material is easier to store due to being square vs round (this also allows more materials to be stored in a smaller area), it allows the wood to dry more evenly, and it is a good way to store lumber that you plan on using but just haven’t decided what you want to do with it yet.

LUMBER WITH A UNIQUE STORY

Clover Construction offers the unique service of on-site log milling with their Woodmizer LT35 portable hydraulic band saw mill. This allows them to mill logs up to 32” in diameter into usable lumber. The mill is mobile, allowing simple setup on site. Clover Construction can also mill at their business location, if preferred.

As a residential General Contractor, many customers must have, or have had, timber cleared from their property during the initial stages of their project. Many of Clover Construction’s Clients choose to mill their logs into usable lumber.

There are some fantastic benefits to milling your own logs: Rough-sawn lumber milled from your own trees is a conversation piece! Our clients have the pleasure of sharing the story of the wood’s origin with their family and friends, which adds to the overall value & enjoyment of their building experience. The “rough-sawn” lumber look is timeless and classic. And lastly, lumber is valuable! Don’t just turn it into firewood, incorporate it in your next project!

This image features a Black Walnut Slab that was “Book- Matched” for a furniture maker to turn into a kitchen table. Book matching is the practice of matching two wood surfaces, so that adjoining surfaces mirror each other, giving the impression of an open book.

CONSIDERATIONS BEFORE MILLING

One popular technique is called “Canting.” A cant is the term used to describe a log that has been edged (squared) on all four sides. Canting logs provides several benefits: the material is easier to store due to being square vs round (this also allows more materials to be stored in a smaller area), it allows the wood to dry more evenly, and it is a good way to store lumber that you plan on using but just haven’t decided what you want to do with it yet.

FEATURED MILLING PROJECTS

Imagine adding a beautiful element into your project through utilizing the timber resources right off your own property! A client by Lake Cle Elum contracted Clover Construction to build a Garage/Shop with Living Space above and storage for their “toys” below. Their build site had two large Douglas Fir trees growing within the footprint of the building site, which required removal before construction. The Clients became excited at the prospect of incorporating lumber from their own trees into their project. Together they decided to use this lumber to create two accent walls in the apartment.

The sawmill has been a great way to meet interesting new people! For example, Bob Danielson lives in Washington and is a world renowned pool cue maker. Bob brought Clover Construction an exotic hardwood called “Pink Ivory” to cut on their mill. Pink Ivory is one of the most elusive, coveted, and highly desirable of all the world’s many exotic woods.

Pink Ivory is an incredibly dense wood & Clover had to buy a special blade for their sawmill. It is 3230 lbf, on the Janka Hardness scale. It was fun to watch the pink sawdust fly as the sawmill labored to get the job done. The resulting lumber had a surprising watermelon-colored hue to it. This lumber has remarkable beauty and Bob’s pool cues are going to be exceptional!

These Clients from Cle Elum, WA were avid sauna users and hired Clover Construction to erect a new building to house their sauna. After explaining Clover’s Portable Log Milling capabilities, the Client agreed that rough-sawn lumber would fit perfectly in their beautiful forested setting. It also saved them money on the price of the lumber needed for the job. Clover Construction milled the framing, board & batt siding, as well as some interior elements using Douglas Fir logs.

Are you interested in taking advantage of lumber on your property and incorporating it into your next build?

Contact Clover Construction to make your on-site log milling dreams come true!

FEATURED CUSTOM BUILDS

Imagine adding a beautiful element into your project through utilizing the timber resources right off your own property! A client by Lake Cle Elum contracted Clover Construction to build a Garage/Shop with Living Space above and storage for their “toys” below. Their build site had two large Douglas Fir trees growing within the footprint of the building site, which required removal before construction. The Clients became excited at the prospect of incorporating lumber from their own trees into their project. Together they decided to use this lumber to create two accent walls in the apartment.

The sawmill has been a great way to meet interesting new people! For example, Bob Danielson lives in Washington and is a world renowned pool cue maker. Bob brought Clover Construction an exotic hardwood called “Pink Ivory” to cut on their mill. Pink Ivory is one of the most elusive, coveted, and highly desirable of all the world’s many exotic woods.

Pink Ivory is an incredibly dense wood & Clover had to buy a special blade for their sawmill. It is 3230 lbf, on the Janka Hardness scale. It was fun to watch the pink sawdust fly as the sawmill labored to get the job done. The resulting lumber had a surprising watermelon-colored hue to it. This lumber has remarkable beauty and Bob’s pool cues are going to be exceptional!

These Clients from Cle Elum, WA were avid sauna users and hired Clover Construction to erect a new building to house their sauna. After explaining Clover’s Portable Log Milling capabilities, the Client agreed that rough-sawn lumber would fit perfectly in their beautiful forested setting. It also saved them money on the price of the lumber needed for the job. Clover Construction milled the framing, board & batt siding, as well as some interior elements using Douglas Fir logs.

Are you interested in taking advantage of lumber on your property and incorporating it into your next build?

Contact Clover Construction to make your on-site log milling dreams come true!

LET’S GET STARTED

LET’S GET STARTED